BubbleFlow CFD

Computational fluid dynamics (CFD) for Bubble Tubing® applications

Computational Fluid Dynamics (CFD)

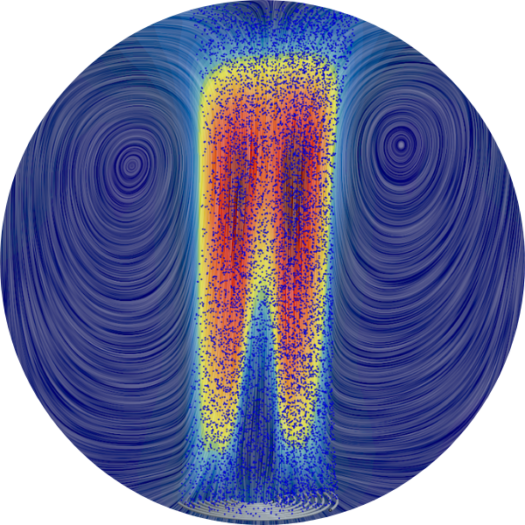

CFD is a science that with the help of digital computers produces quantitative predictions of fluid-flow phenomena based on real world sample data and simulations. As an example, CFD can be used to model a river to understand where the currents are fastest or will have the most impact on infrastructure. In other words, using CFD we can model a body of water to predict how it will act using relevant criteria such as currents and bathymetry.

Using CFD with Bubble Tubing® products allows us to predict the movement of water when it is impacted by the vertical movement of bubbles from the diffuser up to the surface of the water. To accurately simulate real world aquatic environments, we must use complex factors that influence how the waterbody reacts. In the case of de-icing, we can use measurements such as water temperature and density, winds, and historical temperature averages to measure the impact of each line of bubble tubing on ice thickness.

Developing and Validating our BubbleFlow CFD models for Bubble Tubing®

Over the last decade, Bubble Tubing® and C-Core Engineering, an independent research laboratory, have conducted in-depth studies on Bubble Tubing® diffusers to be able to validate three different CFD models for our main industrial applications: deicing, deflection and upwelling.

Our first modeling system was initially developed to measure the effectiveness of Bubble Tubing® as a de-icing system making it possible to be used as a tool for ice management in the engineering phase of projects helping decision makers prior to installation. Our second application was focused on debris such as plastics and more specifically jellyfish deflections using bubble curtains. The latest round of CFD and field validations concentrated its efforts on upwelling currents specific to aquaculture applications like destratification and temperature mixing in upper layers found in fish farms. This research and partnership have yielded new learning and in-depth knowledge about Bubble Tubing® and other products as well as validating our systems as best in class compared to other offers on the market.

Why did we invest in these CFD models?

With over 20 years of experience in water management, we have experienced many of the complexities that this vital resource has thrust upon us and we have been able to adapt to its ever-changing environment. Our investment in validating these CFD models is key to transforming our tacitly acquired experience into real-world and concrete studies that we can share with our clients.

Moreover, our CFD research has helped us reaffirm our current recommendations reflected in our quotes and system designs. We are now even more confident in our abilities to recommend effective and efficient systems.

What does BubbleFlow CFD do for your project?

BubbleFlow is intended to be used during the preliminary stages of a project to explore accurate scenarios to be used during decision-making and to help reach efficiency requirements. Amongst other reasons, investing early on in CFD allows for a better understanding of the project’s predicted results, engineering, and costs for an overall feasibility analysis.

Depending on project requirements and data availability, BubbleFlow allows us to offer reliable predictions on the project’s installation, design, and results. Furthermore, our models have been proven to match real-world results consistently well over 90% accuracy allowing us to be even more confident in our recommendations. Our CFD service allows you to confirm feasibility of a project before even purchasing any material. And all that at a fraction of the cost of the final project.

In addition, investing in CFD modelling early in a project’s life cycle allows for a better understanding of each component of our systems and the costs associated with them. By using CFD modelling, we can therefore optimize and design a variety of propositions depending on the project’s efficiency requirements, budget, or other factors. Since most projects involving Bubble Tubing® are designed for sustained use, CFD simulations can provide a basis for operations and project managers to make long-term decisions.

For instance, a powerplant whose water intake is being blocked by jellyfish could evaluate based on CFD models how much an incremental increase in jellyfish deflection (ex from 80% to 90%) would affect their water intake cleaning costs as well as the opportunity cost of energy production shutdowns. If this incremental increase of jellyfish deflection allows them to clear the water intake only once every month instead of once every week, there is an opportunity to reduce operating costs. When the volume of jellyfish blocking the water intake is unmanageable. BubbleFlow CFD can be used to predict the percentage of jellyfish deflected and bring the volume down to operational levels and avoid shutdowns.

When is BubbleFlow CFD best for your application?

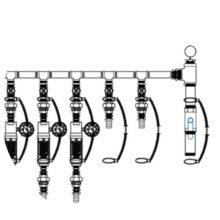

BubbleFlow CFD is currently available for three industrial applications: de-icing, debris deflection and upwelling in aquaculture. If you are unsure of the feasibility of a project or simply want to have a reliable basis for decision making, investing in a CFD simulation will allow you to better understand the forces at work in your water environment as well as ensure that the system’s installation is optimized for your needs. CFD analysis is best if you already have on site data collection of water parameters such as temperature stratification, tidal currents, river flow and bathymetry. We do not collect on site data for this analysis, they must be provided by the client for analysis.

For complex de-icing projects, a CFD model can be created according to precise site conditions such as water intakes and regional parameters such as hours of daylight at northern latitudes and the thickness of ice to ensure your operations are never at risk of ice damage. With experience in the energy industry and industrial installations, we know how valuable continual operations are, preventing maintenance breaks or stoppage of procedures by de-icing key infrastructure can be simulated for extreme conditions.

For debris deflection projects, modelling allows us to test how efficient each possible placement of Bubble Tubing® is at deflecting what needs to be managed, be it for plastics in a river or jellyfish in the sea. These tests can be essential to understanding the limits of the system and allow clients to choose which layouts allows them to reach their optimal efficiency goals.

For aquaculture, we can use CFD models to experiment at solving issues created by rising lakes and ocean temperatures that seasonally threatened farmed fish of mortality and loss of revenues. Degrading water conditions such as sustained high temperatures, jellyfish and algae blooms can have a large impact on farms profitability. Using BubbleFlow CFD, we can recommend best placement and strategy for optimal operations of SalmoAir® upwelling systems to counteract these harmful changes. By modelling the upwelling effect of diffusers and considering on-site water parameters, we can accurately predict how the temperature of the water inside the cages will be to maintain ideal growing conditions for the targeted fish species.

BubbleFlow CFD Consulting Services

Having used these CFD models internally for the last decade, we are now proud to offer them to our clients under the BubbleFlow brand! We value this third party validated science as a reliable method to prove the feasibility of projects that are key to reducing the negative impact that can affect your industries.

If you believe BubbleFlow CFD could be used for a project or is necessary for a project to pass the development stage, please do not hesitate to contact us! We have the experience to adapt these tools to a project’s unique parameters as well as the expertise of over 20 years in water management.

Contact us for additional information or to get an estimate cost for your BubbleFlow CFD Consulting Services.

+1-450-243-0976 or +1-866-249-0976

Who is this application for?

Upwelling & Cage Protection

For fish farms and aquaculture, CFD models help predict the optimal placement of upwelling diffusers to reduce the possibility of harmful algae blooms or fish kills caused by warm masses of water. Moreover, CFD modelling can be used to optimize the placement and design of bubble curtains for HABs mitigation, jellyfish deflection and cage protection.

Water Intake Protection

CFD modelling of powerplant water intakes can be used to optimize the placement of bubble curtains for jellyfish or organic debris deflection. This can be done in the pre-engineering phase or when retrofitting an existing intake with a new bubble barrier.

CFD Modelling

From technology selection to in depth pre-engineering, BubbleFlow CFD allows your firm to be confident in its recommendations as well as offering solid and reliable data for decision-making.